During use Conveyor belt Damage is inevitable. How to repair the damaged conveyor belt?

take Conveyor belt The damaged parts shall be polished with angle grinder and tungsten steel grinding disc.

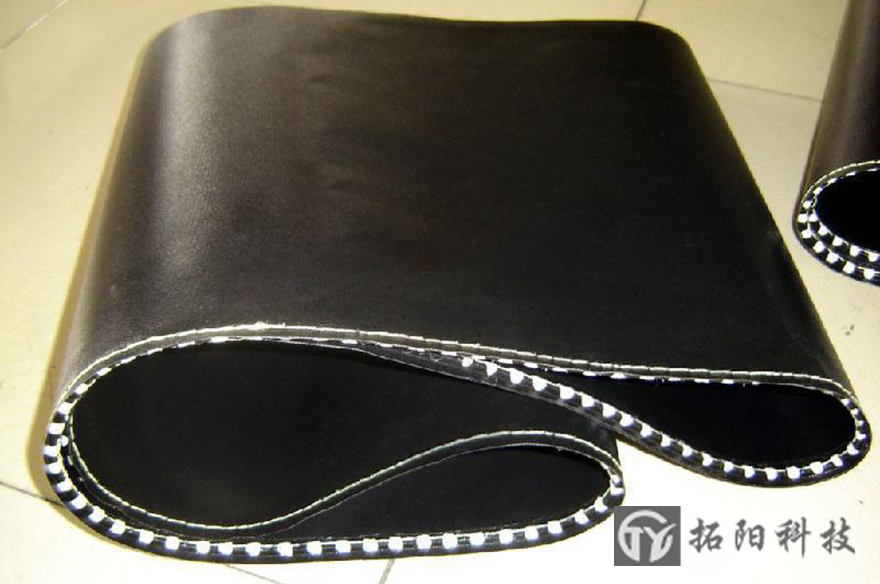

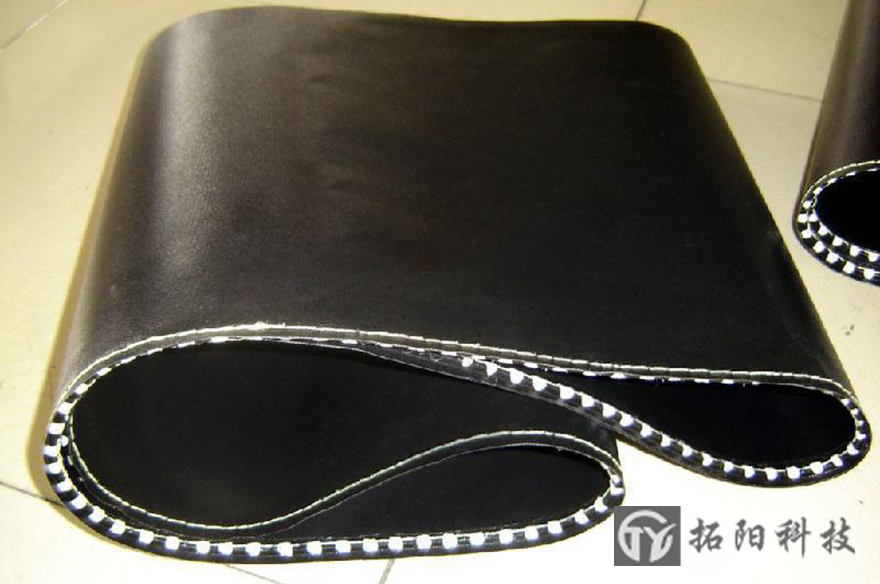

According to the size of the damaged part of the conveyor belt, select the corresponding conveyor belt patch or patch with a semi vulcanized layer (the patch or patch is at least 15~20mm larger than the damaged part). Inmet recommends using the patch or patch with a semi vulcanized layer. For materials without a semi vulcanized layer, it is recommended that the bonding surface be deeply polished.

Brush the belt glue on the damaged part of the conveyor belt and the semi vulcanized surface of the conveyor belt repair strip, leave it in the air for a while, and then paint the second time (leave it in the air until it is not sticky, usually five minutes under normal temperature).

Straighten the repair strip and stick it on the grinding surface of the conveyor belt, and knock and compact it with a rubber hammer or a compaction roller to drive out air.

Conveyor belt manufacturer direct sales

Suzhou Tuoyang New Material Technology Co., Ltd Tips: If the ambient temperature is too low, it is recommended to use iodine tungsten lamp or hot air gun to heat for 0.5-1 hour. If the heating time is allowed to extend properly, it will help to improve the strength of the bonding surface.

according to Teflon conveyor belt The size of the damage shall be at least 15~20mm larger along the damage perimeter, the cutting repair line shall be drawn, the oblique cutting shall be conducted at a 45 degree angle, and the damaged cover glue shall be peeled off. The cloth layer or steel wire layer below shall not be damaged when cutting. 2. The damaged part of the conveyor belt shall be deeply polished with an angle grinder and tungsten steel grinding disc. It is recommended to polish 3mm.

Lay the polished conveyor belt on the fabric reinforcement layer or steel wire reinforcement layer, brush the reinforcement layer and the damaged part with hot vulcanizing agent, cut the periphery of the unvulcanized core rubber into bevel openings, and also apply the hot vulcanizing agent horizontally (the size of unvulcanized surface rubber should be consistent with the size of the damaged part).

Use a hot vulcanizing repair device or vulcanizing machine for pressurization and heating vulcanization.

Warm prompt: the temperature of the vulcanizer controller is controlled between 145-150 ℃. When the temperature of the upper and lower vulcanization plates is stable, start vulcanization for 35-45 minutes. (Depending on the belt thickness, each vulcanized plate can vulcanize about 1mm rubber every 4 minutes.) The water pressure of the vulcanizer can be released after the temperature of the vulcanized plate drops below 70 ℃, and then the vulcanizer can be removed.