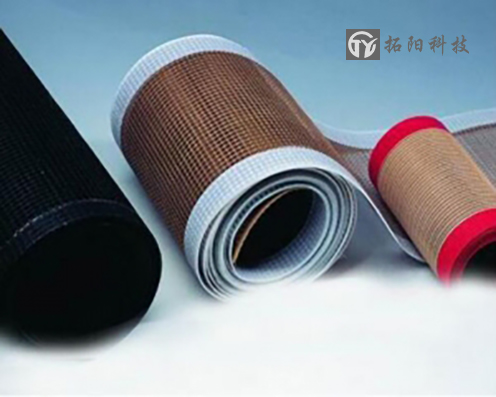

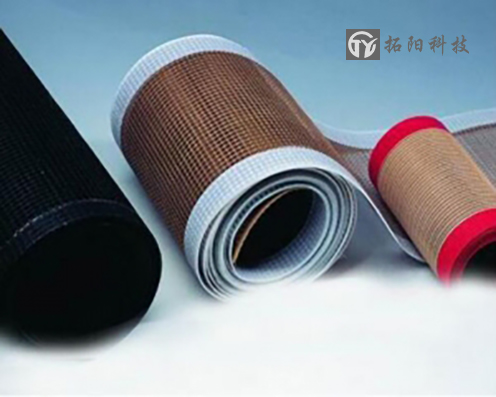

Suzhou Tuoyang New Material Technology Co., Ltd share Conveyor belt Causes and preventive measures of edge wear

Conveyor belt The edge wear is mainly the friction wear between the belt edge and the rack when the conveyor belt deviates. The conveyor belt should run on the center line of the idler group, but due to the defects caused by the manufacturing, installation and use of the conveyor, the conveyor belt often deviates from the center line. Generally, the conveyor belt is allowed to have 5% deviation in the width direction. When the deviation is too much, the conveyor belt will contact with the carrier roller bracket and the rack, resulting in edge rubber wear. When the deviation is serious, the conveyor belt may even be flanged, such as the radial screw head of the roller, the cleaner stop and other convex parts, or the rack gap is too small, which may easily cause the conveyor belt to tear, the covering rubber to peel and scratch locally.

The following precautions are taken:

Through the analysis of the wear factors of the conveyor belt, the corresponding preventive measures are taken in the design of the belt conveyor to extend the life of the conveyor belt. Generally, the design is optimized from the following five aspects to reduce the wear of the conveyor belt.

1. Reasonable selection of conveyor belt

2. Reduce the wear of conveyor parts on the conveyor belt.

3. Structure optimization of feeding device.

4. Reduce the impact of the receiving process on the conveyor belt.

5. Use electromechanical protection device.

The application of conveyor will continue to deepen, and the scope of use will also become wider and wider. However, the characteristics of large investment in conveyor construction, high manufacturing cost of conveyor belt, and heavy maintenance workload, let us continue to deepen our research on how to extend the service life of conveyor and conveyor belt, and the conveyor will be more fully used.