Suzhou Tuoyang New Material Technology Co., Ltd Conveyor belt How to maximize service life:

1. The repair technology for local damage of conveyor belt extends the service life. (1) Local thermal vulcanization; That is to say, the conveyor belt thermal fluidization needs to be equipped with a vulcanizer. (2) Local cold splash, products include liquid polymer composite repair materials of German Diput technology, but it needs to be cured at room temperature for about 10h; (3) For local cold bonding, the repair strip (longitudinal crack) of German Diput Company and cold adhesive - T2 composite adhesive are used to fill the crack plug longitudinally (special glue gun is required). The advantages of these two methods are less manpower and material resources, better wear resistance and reinforcement performance, and shorter recovery time. The disadvantages are that the requirements for the environment are high, and the original belt surface flatness requirements cannot be restored; (4) Spraying repair technology for conveyor belt. This technology is to mix several liquid materials with special equipment, spray them to the wear surface of the belt under high pressure, and spray a certain thickness of wear-resistant layer as required. The curing time is short, and it is suitable for local wear of continuous sheets. The effect is very good. The disadvantage is that special equipment is required.

2. Improve the conveyor belt hopper. Improving the hopper of conveyor belt is one of the effective measures to prevent the early damage of conveyor belt. The dropping hopper at the transfer of each belt conveyor is improved to increase its ability to pass foreign matters by 2.5 times. Long and large foreign matters are not easy to be stuck between the funnel wall and the conveyor belt during the conveying process, reducing the probability of foreign matters tearing the conveyor belt.

3. The guide apron at the hopper makes the gap between it and the conveyor belt larger and larger along the running direction of the conveyor belt, solving the problem that coal and stone are stuck between the conveyor belt and the apron, and eliminating the conveyor belt damage caused thereby.

Suzhou Tuoyang New Material Technology Co., Ltd., located in Guli Town, Changshu, Suzhou, is a manufacturer of a series of high temperature resistant products such as polytetrafluoroethylene and perfluoroethylene. The company has production equipment and R&D personnel with strong technical strength. The R&D team is centered on senior engineers engaged in film and film industry and personnel with rich manufacturing experience.

The products are widely used in instruments, chemicals, machinery, electronics, electrical appliances, aerospace, environmental protection and other fields.

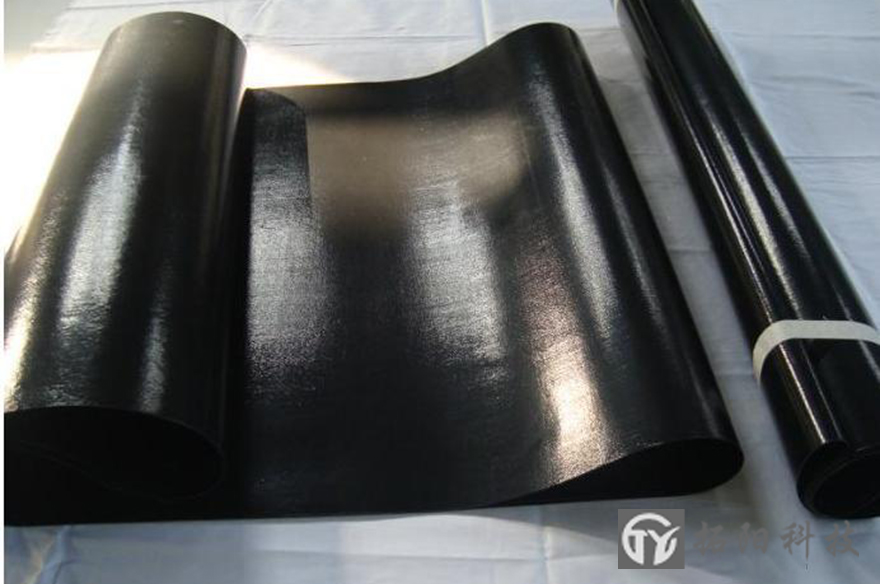

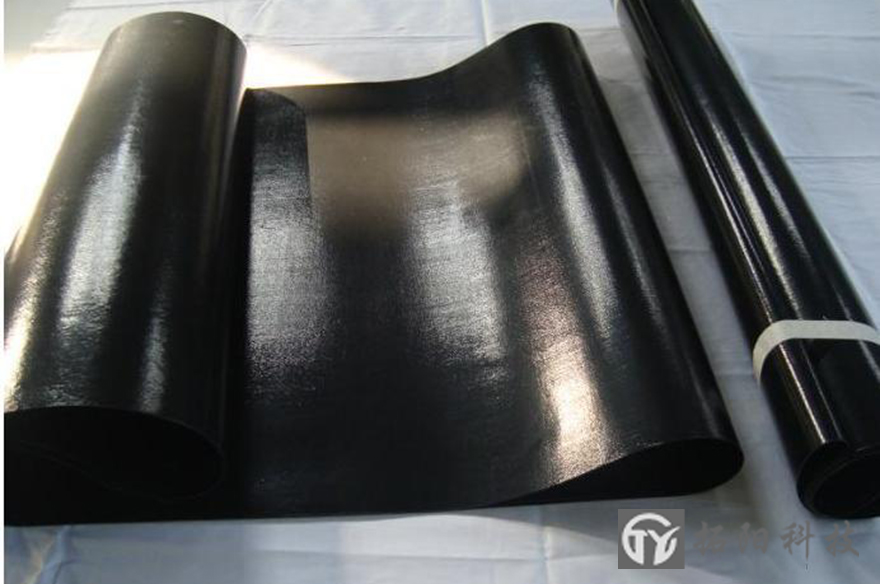

Company production characteristics( iron )Teflon mesh belt, Teflon high temperature cloth, Teflon adhesive tape. Rubber vulcanizing belt Heat shrinking machine mesh belt, tunnel furnace mesh belt, printing machine drying room mesh belt, superheater flocking mesh belt, adhesive machine belt, carpet back adhesive curing belt, laminating machine cloth, sealing machine belt Laminating furnace mesh Glass screen printing drying mesh belt, food drying mesh belt, non-woven products drying mesh belt, electronic products drying cloth belt, microwave drying belt UV belt , food baking plates and other baking ovens; High temperature resistant, anti sticking, hot air flow field for high temperature products. Conventional customization, non-standard customization and processing according to drawings.