Paste on the yarn sizing drum Teflon high temperature tape Benefits and methods of

Teflon high-temperature tape yarn paste roller replaces the traditional Teflon spraying, which has the characteristics of convenience, low technical requirements and durability Teflon tape The service life of the pasting roller is longer. Pay attention to the following technical points:

Clean the surface of the yarn size drum that needs to be pasted with Teflon tape, preferably alcohol as the cleaning agent, and wipe it with a cotton swab. The yarn sizing drum must be smooth, free of iron filings and other impurities, so that the Teflon tape can be better adhered to the drum.

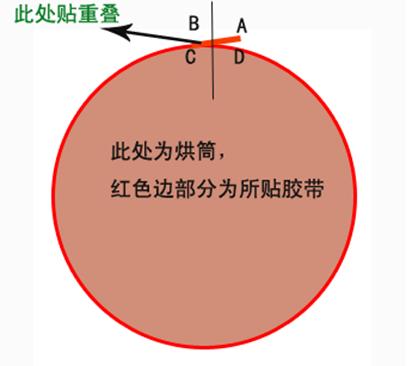

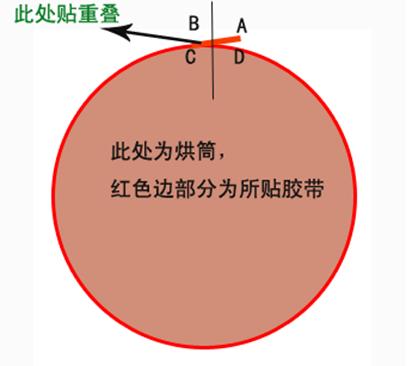

As shown in the figure, when pasting the Teflon tape on the drum, partial overlap is required. Use scissors to cut the Teflon tape about 5cm longer than the required length, and take the cut Teflon tape to the drum edge for backup.

Take the Teflon tape to the roller, slowly tear off the yellow release paper, and at the same time, stick the exposed part of the adhesive surface to the roller, while tearing and pasting. In the process of pasting, you can use soft objects such as cloth or newspaper to rub and flatten the roller where the Teflon tape has been applied, and ensure that both sides of the Teflon tape overlap after pasting.

Use a sharp art knife to cut a straight line in the middle of the overlap of the Teflon tape, tear off the tape at A (as shown in the figure) and open it.

After affixing the Teflon tape, carefully check whether there are small bubbles between the tape and the drying cylinder. If there are small bubbles, you can use a pin and other sharp objects to eliminate them one by one and floor them flat. The tape at B, tear off the tape at C, stick the tape at B, and level the tape at B and D.