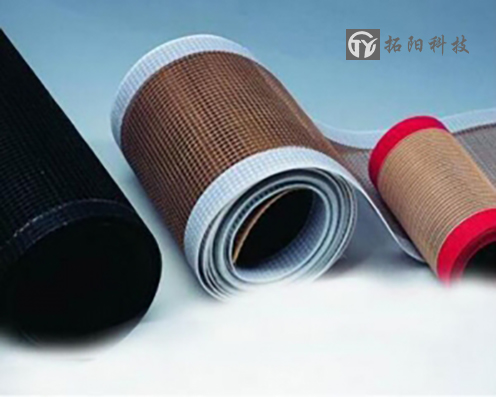

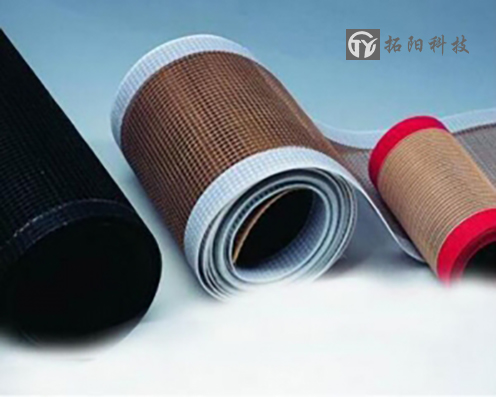

Teflon mesh conveyor belt It has the characteristics of easy permeability of the mesh, so it is widely used in textile printing and dyeing, printing drying guide belt, screen printing, UV drying, UV series, light curing machine, offset printing machine, loose dryer, non-woven drying machine, high cycle dryer, food baking machine guide belt, temperature controlled drying room, rapid drying of flux based ink, drying of general moisture content items and other equipment.

Teflon high temperature cloth has the characteristics of high temperature resistance, low friction coefficient and good insulation, and is widely used in adhesive machines, clothing printing and dyeing machines.

Teflon conveyor belt Features of

1. It is used between low temperature - 70 ℃ and high temperature 260 ℃, with weather resistance and aging resistance. After practical application, if it is kept at 250 ℃ for 200 days, not only the strength will not be reduced, but also the weight will not be reduced; After 120 hours at 350 ℃, the weight is only reduced by about 0.6%; The original softness can be maintained at - 180 ℃.

2. Teflon Conveyor belt Non adhesion: It is not easy to adhere to any substance. Easy to clean all kinds of oil stains, stains or other attachments attached to its surface; Almost all adhesive substances such as paste, resin and paint can be simply removed;

3. It is resistant to chemical corrosion, strong acid, alkali, aqua regia and various organic solvents.

4. Teflon conveyor belt has good dimensional stability (elongation coefficient less than 5 ‰), high strength and good mechanical characteristics.

5. Anti bending fatigue, can be used for small wheel diameter.

6. Drug resistance, non-toxic. It is resistant to almost all medicaments.

7. Fireproof and flame retardant.

8. Air permeability --- air permeability of conveyor belt, reduce heat source consumption and improve drying efficiency.

Methods for prolonging the service time of Teflon conveyor belt:

1: Claw pulley at any concave transition of Teflon conveyor belt. The practice has proved that the transverse strength of the steel rope conveyor belt is insufficient. When starting, the belt pulley causes excessive force on the conveyor belt, leading to tearing of the conveyor belt. The problem can be completely solved by changing the umbrella part of the belt pulley to the belt pulley.

Second: improve the industrial conveyor hopper. Improving the industrial conveyor hopper is one of the effective measures to prevent the early damage of the conveyor belt. The dropping hopper at the transfer of each belt conveyor is improved to increase its ability to pass foreign matters by 2.5 times. Long and large foreign matters are not easy to be stuck between the funnel wall and the conveyor belt during the conveying process, reducing the probability of foreign matters tearing the conveyor belt. The guide apron at the hopper makes the gap between it and the conveyor belt larger and larger along the running direction of the conveyor belt, solving the problem of coal blocks and gift blocks stuck between the conveyor belt and the speech board, and eliminating the conveyor belt damage caused thereby. For the hopper with large drop, the buffer baffle is installed inside to avoid the direct impact of materials on the conveyor belt.